A manual boost controller allows drivers to adjust turbo boost pressure for optimal performance․ It connects to the external wastegate, enabling precise control over boost levels․

1․1 What is a Manual Boost Controller?

A manual boost controller is a mechanical device used to regulate turbocharger boost pressure․ It connects to the external wastegate, allowing drivers to adjust boost levels manually․ The controller uses vacuum lines to direct pressure signals, with arrows on the device indicating the correct direction of airflow toward the wastegate actuator․ This setup enables precise control over boost pressure, enhancing engine performance․ The controller is typically mounted in the engine bay, with color-coded lines (green, blue, black) simplifying installation and ensuring proper connections․

1․2 Purpose of a Manual Boost Controller

The primary purpose of a manual boost controller is to regulate turbocharger boost pressure efficiently․ By connecting to the external wastegate, it allows precise control over boost levels, optimizing engine performance․ The controller ensures proper pressure management, preventing over-boosting and potential engine damage․ It also enhances turbo responsiveness, making it ideal for drivers seeking improved power delivery․ With clear diagrams and color-coded lines, the setup simplifies installation, ensuring secure connections and reliable operation․ This device is essential for tuning engines to achieve maximum performance safely․

1․3 Benefits of Using a Manual Boost Controller

A manual boost controller offers precise control over turbo boost pressure, optimizing engine performance and preventing over-boosting․ It enhances turbo responsiveness, reducing lag and delivering consistent power․ With clear diagrams and color-coded lines, installation is simplified, minimizing errors․ The controller provides reliability and ease of adjustment, making it ideal for tuning engines without complex electronics․ This mechanical solution ensures better engine protection and performance optimization, catering to drivers seeking enhanced power delivery and control․

Key Components of a Manual Boost Controller

The manual boost controller, external wastegate, and tubing connections are essential components ensuring precise boost control and proper operation in turbocharged engines․

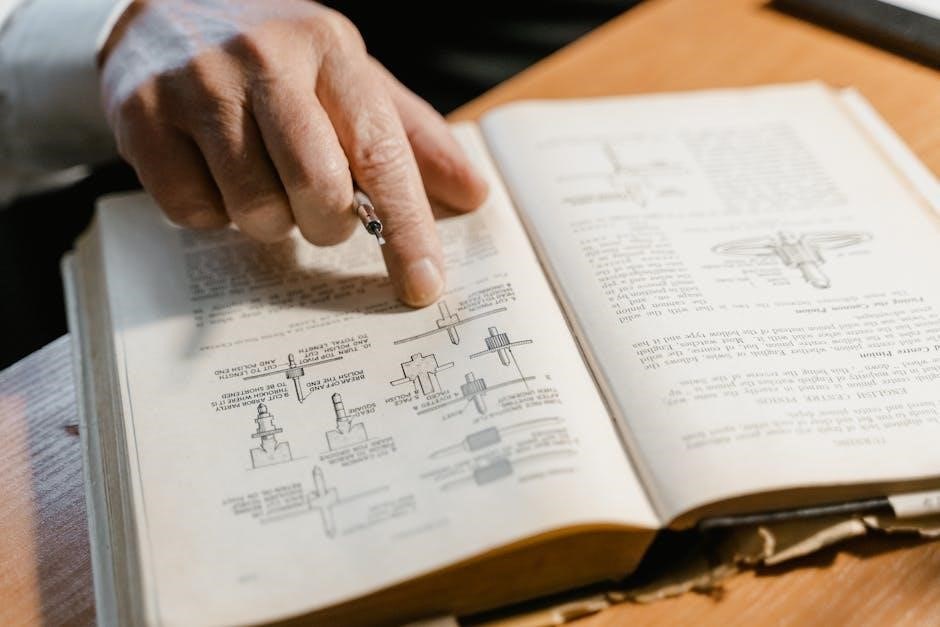

2․1 Diagram Overview

A manual boost controller diagram typically illustrates the key components and their connections․ At the center is the boost controller, which regulates pressure․ The external wastegate is shown separate from the turbocharger, with arrows indicating vacuum and boost lines․ Tubing and hose connections are highlighted, showing how they link the controller to the wastegate and engine․ Color-coded lines often represent different pressures, such as green for vacuum and blue for boost․ This visual guide helps in understanding how each part interacts to manage boost levels effectively in a turbocharged engine setup․

2․2 External Wastegate and Its Role

The external wastegate is a critical component in a manual boost controller system, responsible for regulating excess turbocharger boost pressure․ It diverts exhaust gases away from the turbine when pressure exceeds the set limit, preventing over-boosting․ The wastegate actuator receives signals from the boost controller to open or close the valve․ Proper functioning ensures optimal boost levels, protecting the engine from damage․ The external design allows for precise control and is often preferred for its reliability and ease of adjustment compared to internal wastegates․

2․3 Tubing and Hose Connections

The tubing and hose connections in a manual boost controller system are critical for directing airflow and maintaining proper boost pressure․ High-quality, heat-resistant materials like silicone or stainless steel are typically used to ensure durability․ These connections link the controller to the wastegate, turbocharger, and intake manifold, ensuring precise communication․ Proper routing and secure connections are essential to prevent kinking, blockages, or leaks, which could disrupt boost pressure regulation․ Regular inspection of these components is recommended to maintain optimal performance and avoid potential issues․

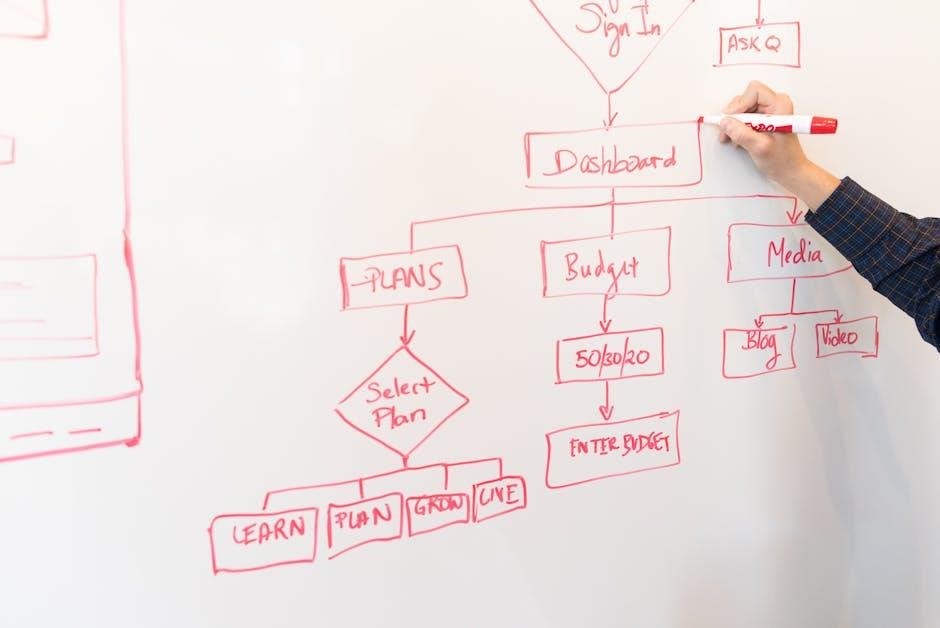

Installation Steps for a Manual Boost Controller

- Plan the setup to ensure proper placement of components․

- Connect the controller to the external wastegate securely․

- Mount the controller in a stable engine bay location․

- Route vacuum lines carefully to avoid interference․

- Test the system thoroughly to confirm functionality․

3․1 Planning the Installation

Planning the installation of a manual boost controller involves assessing the engine bay layout to determine the optimal placement of the controller and external wastegate․ Consult the diagram to identify the correct connections and ensure compatibility with your vehicle’s turbo system․ Gather all necessary tools and materials, such as wrenches, vacuum hoses, and T-fittings․ Reference the manufacturer’s guide for specific recommendations․ Route the vacuum lines and electrical connections to avoid interference with moving parts․ Ensure the wastegate actuator is properly aligned and securely attached․ Double-check the boost pressure settings to prevent over-boosting during initial setup․

- Verify the wastegate’s operation before connecting it to the controller․

- Ensure all fittings are compatible with your vehicle’s specifications․

3․2 Connecting the Controller to the Wastegate

Connect the manual boost controller to the external wastegate by attaching the appropriate vacuum hose to the controller’s output port․ Refer to the diagram to ensure the correct orientation and connection points․ Use the provided fittings to secure the hose to the wastegate actuator․ Tighten the connections firmly but avoid over-tightening, which could damage the threads․ Double-check the alignment to ensure proper communication between the controller and wastegate․ This step is critical for maintaining precise boost control․

- Use compatible fittings to prevent leaks or restriction․

- Ensure the vacuum hose is free from kinks or obstructions․

- Verify the connection by gently tugging on the hose․

3․3 Mounting the Controller in the Engine Bay

Mount the manual boost controller in a secure, accessible location within the engine bay․ Use the provided mounting bracket or choose a sturdy spot like the firewall or fender well․ Ensure the controller is protected from direct heat sources, such as the turbocharger or exhaust manifold․ Secure the controller firmly to prevent vibration-related issues․ Keep it away from moving components to avoid damage․ Refer to the diagram for ideal placement and orientation․

- Choose a location with adequate clearance for adjustments․

- Use screws or bolts to firmly attach the controller․

- Ensure the controller is level for accurate operation․

3․4 Routing the Vacuum Lines

Properly routing the vacuum lines ensures reliable operation of the manual boost controller․ Use high-quality vacuum hose resistant to heat and pressure․ Route the lines away from moving components and high-heat sources․ Avoid kinks or unnecessary bends that could restrict airflow․ Secure the lines with zip ties to prevent damage․ Ensure connections are tight and free from leaks․ Refer to the diagram for correct routing paths․ Test the system after installation to confirm proper function․

- Use heat-resistant vacuum hose for durability․

- Keep lines away from engine components․

- Check for leaks before finalizing the setup․

3․5 Testing the Setup

After installation, test the manual boost controller setup thoroughly․ Start by ensuring all connections are secure and free from leaks․ Turn on the engine and monitor the boost pressure gauge to verify it reaches the desired level․ Check for any unusual noises or fluctuations․ Gradually increase the throttle to observe how the boost responds․ Ensure the wastegate opens and closes correctly by listening for the distinctive “psssst” sound․ Fine-tune the adjustments if boost levels are inconsistent․ Finally, take the car for a drive to test under various conditions, paying attention to performance and stability․

- Inspect connections for leaks or damage․

- Monitor boost levels during acceleration․

- Listen for proper wastegate operation․

Understanding the Diagram

The diagram provides a visual guide to the manual boost controller’s components and connections, essential for installation and troubleshooting, and clarifying key relationships between parts․

4․1 Interpreting the Arrows on the Controller

The arrows on the manual boost controller diagram indicate the flow of air and vacuum signals․ They show how air pressure moves from the turbocharger to the wastegate actuator․ Green arrows often represent boost pressure pathways, while blue arrows signify vacuum lines connected to the solenoid or controller․ Properly following these arrows ensures correct connections between the controller, external wastegate, and engine components, which is essential for precise boost control and optimal engine performance․

4․2 Color Coding of Lines (Green, Blue, Black)

In the manual boost controller diagram, color-coded lines simplify installation and troubleshooting․ Green lines typically represent the boost pressure source from the turbocharger to the wastegate․ Blue lines often indicate vacuum or signal lines connected to the controller or solenoid․ Black lines may denote reference vacuum or other auxiliary connections․ This color coding helps in identifying and routing each line accurately, ensuring proper communication between components like the external wastegate and the controller for precise boost regulation and engine performance optimization․

4․3 Wastegate Actuator Connection Points

The wastegate actuator connects to the manual boost controller via specific ports․ Typically, there are two main connection points: one for the boost pressure signal and another for the vacuum source․ The boost signal port links to the turbocharger’s compressor housing, while the vacuum port connects to the engine’s intake manifold․ Proper alignment and secure connections are critical to ensure accurate boost control․ Referencing the diagram helps identify these points, ensuring the actuator operates smoothly with the external wastegate for optimal boost regulation and engine performance․

Tuning and Adjusting the Boost Controller

Tuning involves adjusting settings to achieve desired boost levels, monitoring performance, and ensuring optimal function․ Proper adjustment requires a boost gauge and careful calibration for peak efficiency and reliability․

5․1 Setting the Desired Boost Level

Setting the desired boost level involves adjusting the manual controller to achieve the target pressure․ Refer to the diagram for guidance on connections and operation․ Start by turning the adjustment knob to the desired setting, ensuring the wastegate actuator is properly connected․ Use a boost gauge to monitor pressure accurately․ Always begin with a lower setting and gradually increase to avoid over-boosting․ Test the system under load to confirm stability and performance․

Consult the diagram for specific connection points and ensure all lines are securely attached․ Adjustments should be made carefully to prevent damage to the turbo or engine․

5․2 Adjusting the Controller for Optimal Performance

Adjusting the manual boost controller for optimal performance requires fine-tuning the settings based on engine response․ Start with small increments, testing boost levels under varying conditions to ensure stability․ Use a boost gauge to monitor pressure and adjust the knob accordingly․ Refer to the diagram to ensure proper vacuum line routing․ Fine-tune the wastegate actuator sensitivity to maintain consistent boost․ Avoid aggressive adjustments that may cause over-boosting, and always test under load to confirm performance gains․

5․3 Monitoring Boost Pressure

Monitoring boost pressure is essential to ensure the system operates within safe and desired limits․ Install a high-quality boost gauge to track pressure levels accurately․ Mount the gauge in the engine bay or dashboard for easy visibility․ Regularly check the gauge during acceleration and idle to verify stability․ Look for fluctuations or unexpected drops, which may indicate leaks or wastegate issues․ Use the gauge readings to fine-tune the controller and maintain optimal performance without risking engine damage from over-boosting․

Common Mistakes to Avoid

6․1 Incorrect Hose Connections

Incorrectly connecting hoses can lead to vacuum leaks or improper boost pressure regulation․ Always use the correct fittings and ensure connections are secure and routed properly․

Incorrect hose connections are a common issue when installing a manual boost controller with an external wastegate․ Using the wrong fittings or misrouting vacuum lines can lead to boost leaks, inaccurate pressure regulation, and reduced engine performance․ Ensure all connections are secure, properly aligned, and free from damage․ Double-check the diagram to confirm correct routing of the green, blue, and black lines to avoid mixing vacuum sources․ Loose or improperly sealed connections can also result in over-boosting or wastegate malfunction, emphasizing the importance of precise installation․

6․2 Improper Mounting Locations

Improper mounting locations for a manual boost controller can disrupt its functionality and lead to inconsistent boost pressure․ Avoid placing the controller near heat sources like the turbocharger or exhaust manifold, as excessive heat can damage the internal components․ Additionally, mounting it in areas with high vibration may cause loose connections or mechanical failure over time․ Ensure the controller is securely fastened in a cool, stable location within the engine bay, ensuring easy access for adjustments while maintaining proper function and reliability of the system․

6․3 Over-Tightening or Under-Tightening Fittings

Over-tightening or under-tightening fittings on a manual boost controller can lead to leaks or damage․ Over-tightening may strip threads or crack components, while under-tightening can result in loose connections and boost leaks․ Always use the recommended torque specifications for fittings to ensure proper sealing without damaging the controller or connected components․ Additionally, check for any signs of wear or damage during installation and consider using thread sealant to prevent vacuum leaks․ Properly secured fittings are essential for maintaining consistent boost pressure and system reliability․

Troubleshooting Tips

Troubleshooting a manual boost controller involves identifying issues like boost leaks, vacuum line disconnections, or wastegate actuator malfunctions․ Refer to the detailed sub-sections below for solutions․

7․1 Diagnosing Boost Leaks

Diagnosing boost leaks involves checking for signs like decreased boost pressure or engine performance issues․ Inspect all connections, including the external wastegate and vacuum lines, for cracks or loose fittings․ Use a boost leak tester or apply soapy water to suspect areas to identify escaping air․ Refer to the manual boost controller diagram to ensure all components are securely connected․ Addressing leaks promptly prevents damage to the turbocharger and maintains optimal boost control․

7․2 Fixing Vacuum Line Issues

Vacuum line issues can disrupt boost control, causing poor engine performance․ Inspect lines for cracks, cuts, or loose connections․ Replace damaged sections with high-quality, heat-resistant tubing․ Ensure all fittings are securely tightened but avoid over-tightening, which can damage threads; Refer to the manual boost controller diagram to verify proper routing and connections․ Use vacuum line diagrams to identify the correct placement and routing․ Testing the system after repairs ensures proper function and prevents further issues․

7․3 Resolving Wastegate Actuator Problems

Wastegate actuator issues can lead to inconsistent boost pressure․ Start by inspecting the actuator for dirt or debris, which can cause sticking․ Clean the actuator with a solvent and ensure proper lubrication․ Check the spring tension; if it’s too loose or tight, adjust or replace it․ Verify the actuator rod is aligned and not bent․ Ensure the actuator is securely connected to the boost controller․ If problems persist, consult the external wastegate diagram for proper installation and operation guidelines․

Safety Considerations

Always wear protective gear during installation․ Ensure proper tools are used to avoid damage․ Regularly inspect connections for leaks and secureness to maintain system stability and safety․

8․1 Proper Safety Gear During Installation

Always wear gloves, safety glasses, and a face mask when installing a manual boost controller․ Gloves protect against cuts and abrasions, while safety glasses shield eyes from debris․ A face mask prevents inhaling dust or particles during drilling or vacuum line routing․ Additionally, use steel-toe boots and a workshop apron for extra protection․ Ensure proper tools are used to avoid slipping or damaging components․ Familiarize yourself with the diagram to understand connections and components better․ Safety gear is essential to protect against potential hazards during the installation process․

8․2 Avoiding Over-Boosting

Over-boosting can damage your engine, so it’s crucial to set the correct boost level․ Use the manual boost controller to regulate pressure, ensuring it aligns with your engine’s specifications․ The external wastegate helps relieve excess pressure, preventing over-boosting․ Start with a lower boost setting and gradually increase while monitoring performance․ Always use a boost gauge to track pressure accurately․ Avoid aggressive adjustments without testing․ Regularly inspect connections and the wastegate for proper function․ This ensures safe and reliable operation of your turbo system․

8․3 Ensuring Secure Connections

Secure connections are vital for proper functionality and safety․ Always use high-quality tubing and fittings designed for boost applications․ Check all connections for tightness, but avoid over-tightening, which can damage threads or hoses․ Inspect the external wastegate and vacuum lines regularly for signs of wear or leaks․ Use heat-resistant materials for components near the turbocharger․ Ensure all fittings are compatible with the system’s pressure ratings․ Regularly monitor connections after installation to prevent boost leaks or system failure․ Follow manufacturer guidelines for torque specifications and material recommendations․

Effective use of a manual boost controller with an external wastegate enhances engine performance and efficiency․ Proper installation and tuning ensure optimal results and reliability over time․

9․1 Summary of Key Points

A manual boost controller with an external wastegate is a straightforward yet effective tool for managing boost pressure in turbocharged engines․ It allows drivers to adjust boost levels manually, providing better control over engine performance․ Proper installation ensures reliable operation, while tuning the controller optimizes power delivery․ The external wastegate plays a critical role in regulating excess boost pressure, preventing over-boosting․ By following the diagram and manufacturer guidelines, users can achieve enhanced engine efficiency and responsiveness, making it a valuable upgrade for performance enthusiasts․

9․2 Final Tips for a Successful Installation

For a flawless manual boost controller installation, ensure all connections are secure and properly routed to avoid damage․ Double-check the wastegate actuator wiring and vacuum lines for any leaks or kinks․ Refer to the provided diagram to confirm accurate line routing and connections․ Test the system gradually, starting with low boost settings, and monitor performance closely․ Adjustments should be made incrementally to avoid over-boosting․ Finally, consult additional resources or seek professional advice if uncertainties arise during the process․

Further Resources

Consult the manufacturer’s guide for specific installation details․ Check online forums for troubleshooting tips and expert advice․ Purchase repair kits from trusted automotive suppliers․

10․1 Recommended Tools and Materials

For a successful manual boost controller installation, gather essential tools: an adjustable wrench, pliers, Teflon tape, and vacuum line connectors․ Use high-quality materials like stainless steel or silicone hoses for durability․ Ensure you have a boost gauge for monitoring and a wiring kit if needed․ Proper tools and materials ensure reliability and prevent leaks or failures․ Always verify compatibility with your vehicle’s specific turbo and wastegate setup for optimal performance and safety․

10․2 Suggested Reading for Advanced Tuning

For advanced tuning, explore manufacturer-specific boost controller manuals and technical guides․ Study online forums and communities dedicated to turbocharged engines․ Books on turbocharger systems and boost management offer in-depth insights․ Additionally, refer to detailed diagrams and case studies from automotive tuning experts․ These resources provide practical tips and troubleshooting techniques for optimizing your manual boost controller setup․ Always consult the manufacturer’s instructions for model-specific guidance․

10․3 Manufacturer Instructions and Guides

Always refer to the manufacturer’s instructions for specific guidance on your manual boost controller․ Diagrams and wiring details are often provided to ensure proper installation․ Brands like GReddy or Turbosmart include detailed manuals with troubleshooting tips․ These guides typically cover external wastegate configurations and boost pressure settings․ Follow the recommended procedures to avoid voiding warranties or causing system damage․ Manufacturer instructions are tailored to your specific model, ensuring compatibility and optimal performance․ They also outline safety protocols and maintenance schedules for long-term reliability․